Design Considerations for IC Substrates and Chiplet Integration

Yaniv Maydar

|25th March ,2025

Abstract

The increasing complexity of semiconductor packaging and integration has led to advanced IC substrate manufacturing techniques, particularly for applications involving high-speed signals, flip-chip assembly, wire bonding, and thermal compression. Furthermore, chiplet-based architectures are gaining traction due to their modularity and scalability. This paper explores the key considerations and parameters for IC substrate design, high-speed interconnects, and chiplet integration to ensure optimal performance, manufacturability, and reliability.

Introduction

As semiconductor technologies advance, the demand for high-performance IC substrates has grown. These substrates must support fine-line interconnections, ensure signal integrity, manage power efficiently, and dissipate heat effectively. Additionally, emerging packaging techniques such as chiplets necessitate new design paradigms for integration and interconnect standardization.

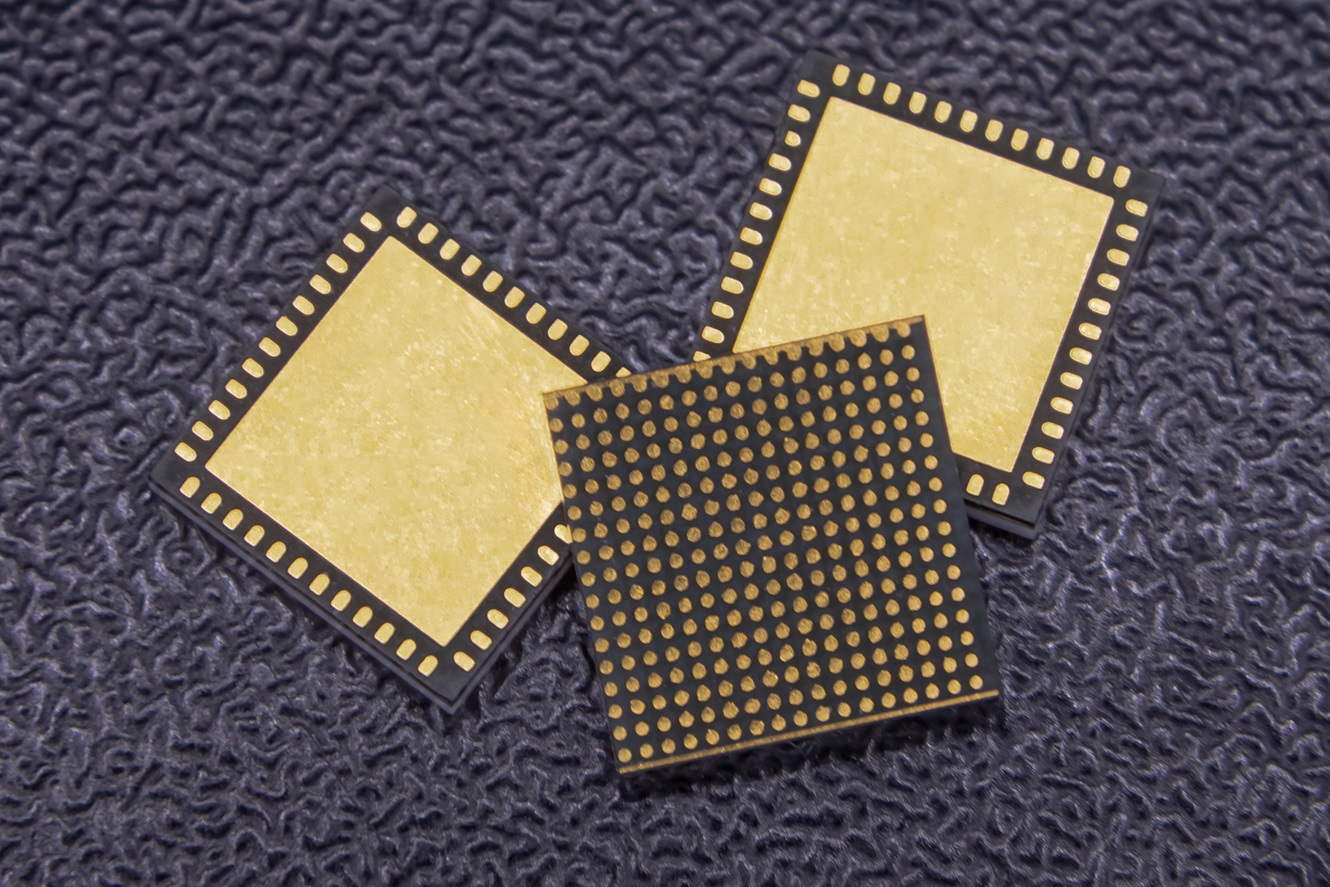

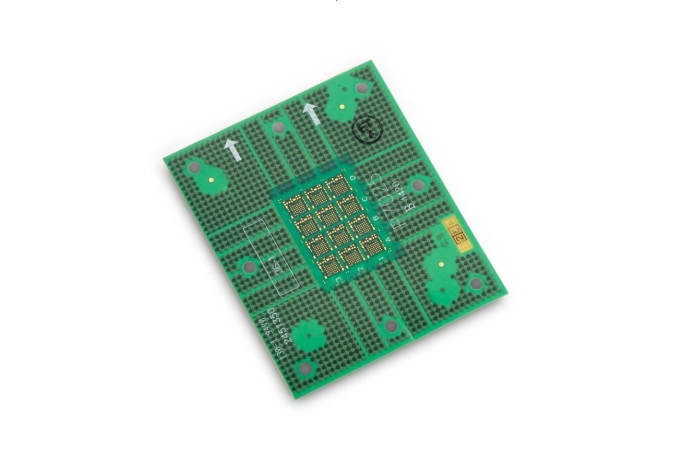

IC Substrate Manufacturing Considerations

IC substrates serve as the foundation for semiconductor devices, requiring precise material selection, design considerations, and manufacturing processes.

Material Selection

-

- Core Materials: FR-4 (for lower-end applications), BT (Bismaleimide Triazine) resin, Ajinomoto Build-up Film (ABF), Polyimide (PI), and other high-performance materials.

- Copper Foil: Thin copper layers with low surface roughness to reduce signal loss.

- Dielectric Materials: Low dielectric constant (Dk) and low dielectric loss tangent (Df) for high-frequency applications.

High-Speed Line Design Considerations

For high-speed applications, signal integrity, impedance control, and transmission loss minimization are critical.

-

- Controlled Impedance: Precise trace width and spacing to achieve target impedance (e.g., 50Ω, 100Ω differential pairs).

- Low-Loss Dielectric Materials: Reducing signal attenuation at high frequencies.

- Via Design: Microvias and back-drilled vias to reduce impedance discontinuities.

- Power Integrity & Return Paths: Continuous ground planes and optimized power distribution networks (PDNs) for stable operation.

IC Substrate Requirements for Various Assembly Methods

Different assembly methods impose distinct requirements on IC substrates.

Flip-Chip Assembly

-

- High-Density Routing: Sub-10µm line/space design for fine-pitch interconnections.

- Low Warpage: Ensuring reliable bump connections.

- Underfill Compatibility: Supports underfill flow to enhance mechanical strength.

- Surface Finish: ENEPIG or ENIG to improve solderability and reliability.

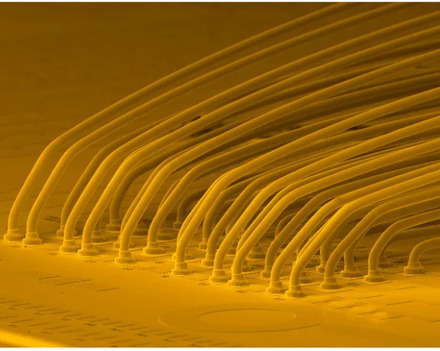

Wire Bonding

-

- Bond Pad Design: Sufficient pad size and spacing for wire attachment.

- Surface Finish: OSP, ENEPIG, or soft-gold plating for gold wire bonding.

- Mechanical Strength: Dielectric layers should withstand wire bonding forces.

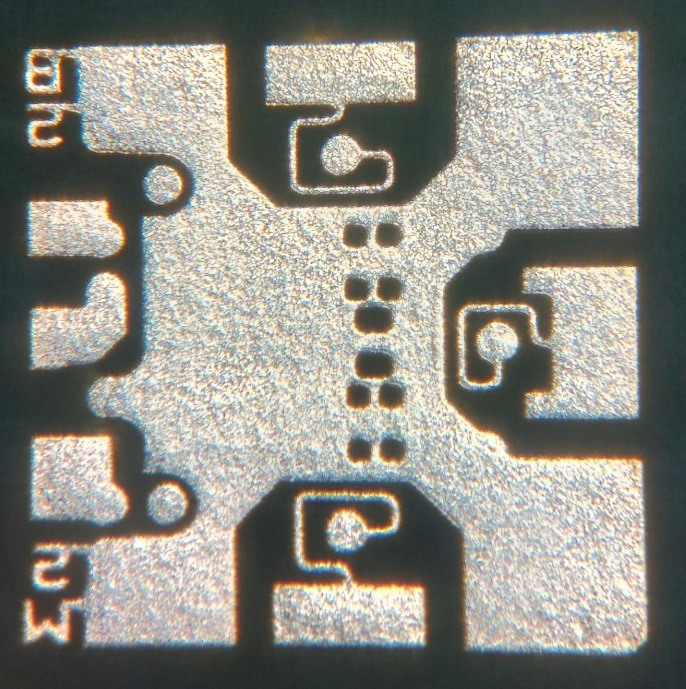

Thermal Compression Bonding

-

- Fine-Line Patterning: ≤2µm line/space for advanced interposers.

- Heat Resistance: Materials must endure bonding temperatures of 250-350°C.

- Low Warpage & Tight Tolerances: Prevent misalignment during compression bonding.

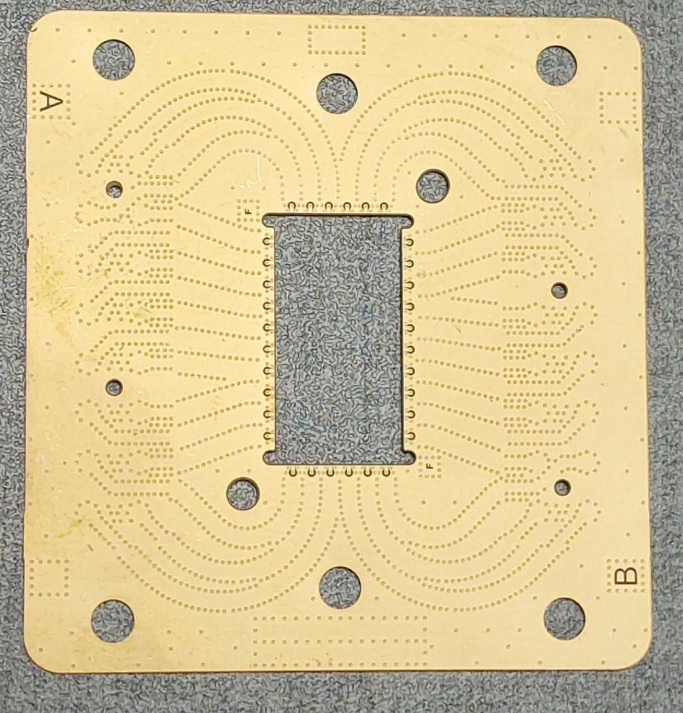

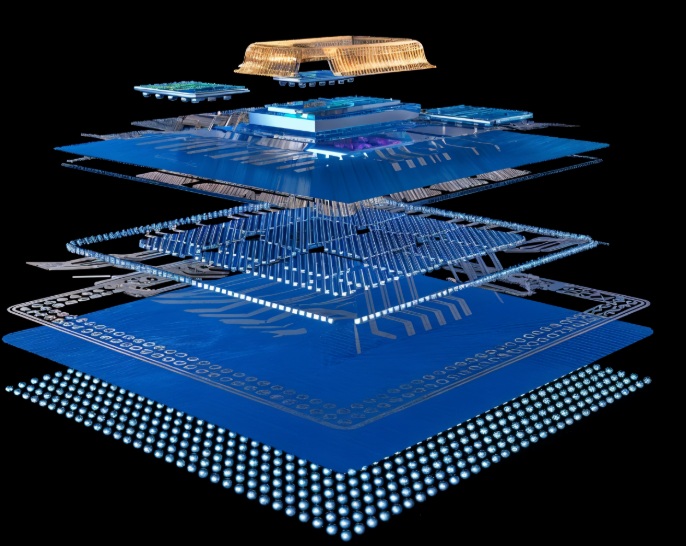

Chiplet Integration Considerations

Chiplets enable modular architectures, requiring careful interconnect and packaging strategies.

Interconnect Technologies

-

- 2.5D Integration (Silicon Interposers): High-bandwidth, low-latency connections using Through-Silicon Vias (TSVs).

- 3D Integration (Die Stacking): Vertical interconnections using microbumps or hybrid bonding.

- Organic Interposers: Cost-effective alternative to silicon interposers.

Signal & Power Integrity

-

- High Bandwidth Density: Short interconnects to minimize latency.

- Low-Resistance PDN: Reduces IR drop and voltage noise.

- Integrated Voltage Regulators (IVRs): Enhances power efficiency.

Thermal Management

-

- Die-to-Die Thermal Coupling: Optimized die placement to reduce hotspots.

- Thermal Interface Materials (TIMs): Enhances heat dissipation.

- Active Cooling: Liquid cooling and microfluidic solutions for high-power chiplets.

Yield & Reliability

-

- Known-Good Die (KGD) Testing: Ensures only functional chiplets are integrated.

- Redundant Interconnects: Fault-tolerant design to prevent failures.

Standardization Efforts

-

- UCIe (Universal Chiplet Interconnect Express): High-bandwidth, low-power chiplet interconnect standard.

- BoW (Bunch of Wires): Simplified interconnect for cost-sensitive applications.

There are many applications in which there is a need for these technologies

The following are the main ones:

High-Performance Computing (HPC)

-

- AI Accelerators and Server Chips: Chiplet architectures enhance computational power and efficiency in HPC systems. For instance, Egis Technology’s collaboration with Arm aims to accelerate the commercialization of Arm-based chiplet technology in AI HPC server chips, combining specialized integrated circuit design with Arm’s power-efficient architecture.

- Advanced Processors: Companies like AMD have implemented chiplet designs in their EPYC-family processors, leveraging existing organic build-up substrate technology to enhance performance and scalability.

Medical Devices

-

- Imaging Systems: Advanced IC substrates enable high-density interconnections (HDI PCBs) essential for medical imaging equipment, such as MRI and CT scanners, ensuring precise signal transmission for accurate diagnostics. See Medical PCBs.

- Portable Diagnostic Tools: Chiplet technologies facilitate the miniaturization of handheld diagnostic devices, integrating various functions like signal processing and data transmission, thereby enhancing portability and functionality.

Defense

-

- Radar and Communication Systems: The defense sector utilizes IC substrates and chiplet technologies to develop sophisticated radar and secure communication systems, benefiting from the high performance and reliability these technologies offer. See Radar PCBs and Military PCBs.

- Electronic Warfare Equipment: Chiplet architectures allow for rapid upgrades and customization in electronic warfare tools, providing adaptability to emerging threats.

Aerospace

-

- Avionics: Advanced IC substrates contribute to the development of reliable avionics systems, which are crucial for navigation and communication in aircraft. See Aerospace PCBs.

- Satellite Systems: Chiplet technologies enable the integration of various functionalities within satellites, optimizing performance while minimizing weight and power consumption, which are critical factors in aerospace applications

Conclusion

IC substrate design and chiplet integration require meticulous planning to balance performance, manufacturability, and cost. As semiconductor technologies evolve, advanced interconnect solutions, high-speed signaling techniques, and thermal management strategies will be critical for ensuring reliability and efficiency.

Future Work

Future developments should focus on improving interconnect density, reducing power consumption, and exploring novel materials for next-generation semiconductor packaging.

iNPACK’s Multidisciplinary Approach to Advanced Substrate and Chiplet Integration

At the intersection of engineering excellence and strategic product management, iNPACK brings a multidisciplinary approach that transforms IC substrate and chiplet integration challenges into streamlined, scalable solutions. Leveraging deep expertise across thermal, electrical, and mechanical domains, iNPACK ensures every design balances high-speed signal integrity, thermal reliability, and power efficiency. By aligning advanced packaging capabilities with agile product lifecycle management, the company accelerates time-to-market while maintaining rigorous quality and compliance standards. iNPACK’s holistic integration of design-for-manufacturability enables customers to confidently adopt cutting-edge technologies like 2.5D and 3D integration, organic interposers, and miniaturized architectures—delivering performance and reliability in even the most demanding applications, from AI servers to medical imaging and aerospace systems.

Looking for IC Packaging Services and Solutions? Contact Us today.