Advanced Packaging

Advanced Packaging is a blanket term used to describe a general grouping of various distinct methodologies. Advanced Packaging technologies include: 2.5D, 3D, Fan-Out (2D), Wafer Level Packaging and System-in-Package (SiP).

About System-in-Package (SiP) Technology

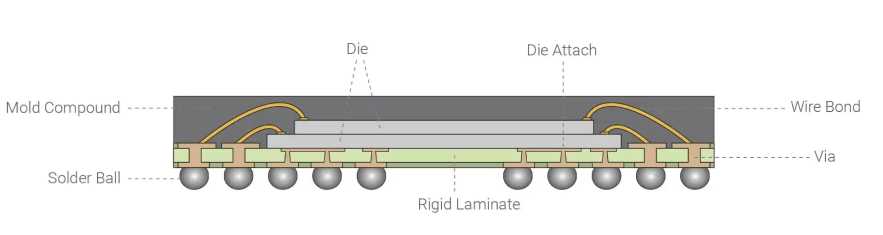

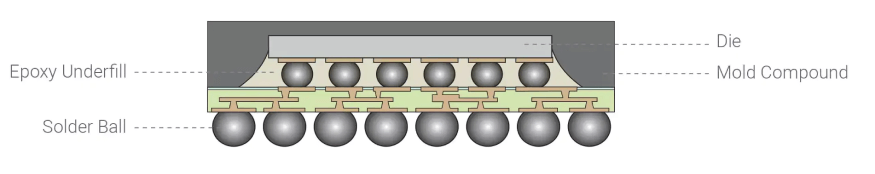

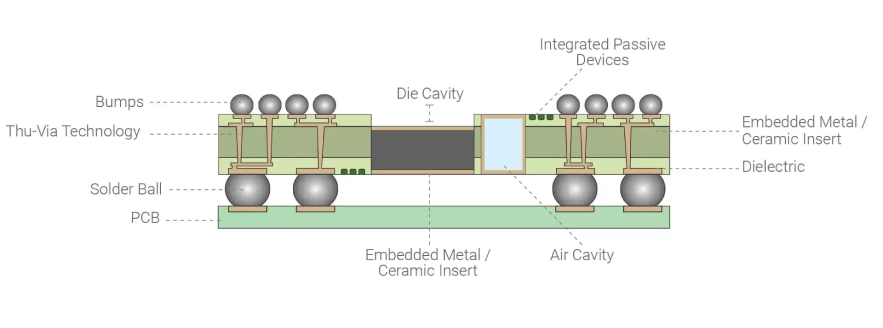

SiP is a combination of multiple active electronic components of diverse functionality, assembled in a single unit, that performs multiple functions associated with a system or sub-system.

SiP may optionally contain passives, MEMS, optical components and other packages or devices; including a combination of bare dies and SMT components.

SiP is designed to be a complete system within a single package, whereas a Multi-Chip-Module (MCM), containing two or more interconnected chips, isn’t necessarily a complete system.

Advanced Packaging Technologies

SiP / MCM Packaging

Heterogenous Integration

3D / 2.5D Packaging

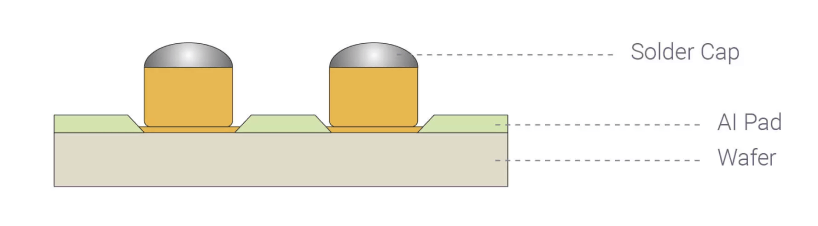

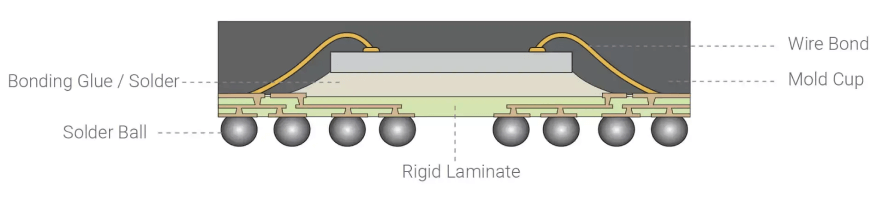

2D Packaging = Integration method of mounting 2 or more dies horizontally on the surface of the substrate:

Takes up less space and provides more functionality compared with SMT

CTE matching, reinforced structure, good thermal dissipation solution

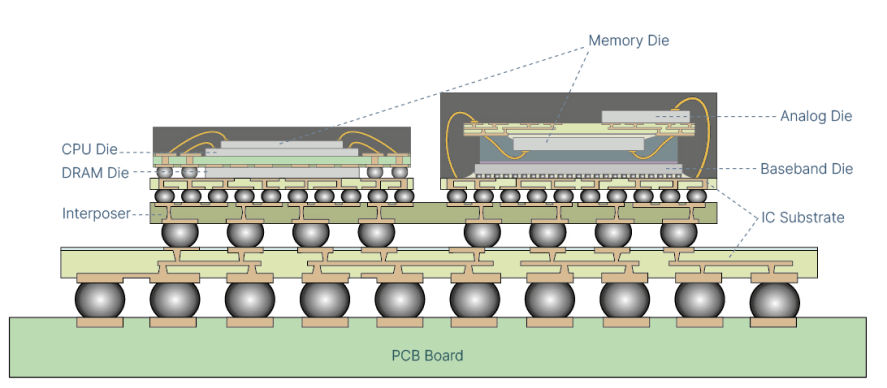

2.5D Packaging = 2 or more active semiconductor chips placed side-by-side on a silicon interposer for extremely high die-to-die interconnect density:

Takes up less space than 2D, when using high IO dies

Improved thermal and CTE matching

Reinforced structure

3D Packaging = Multiple layers/chips/wafers, stacked vertically and electrically interconnected, to enable die-on-die and package-on-package solutions:

Optimizes functionality

Superior system design featuring thermal, CTE and structural advantages