Design For Manufacturing (DFM)

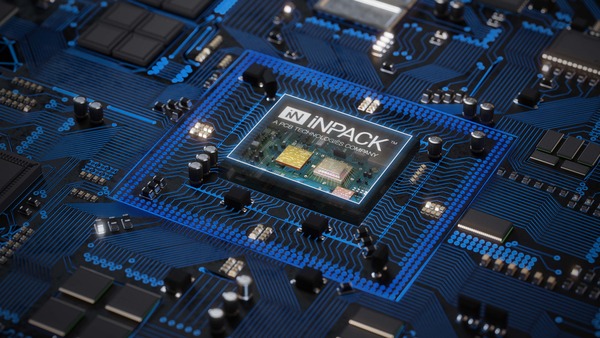

A key aspect of advanced packaging technologies, DFM aims to ensure that package design can be manufactured efficiently and reliably; featuring high yields and lower costs. DFM considerations are crucial throughout the packaging design process, from initial concept to final production.

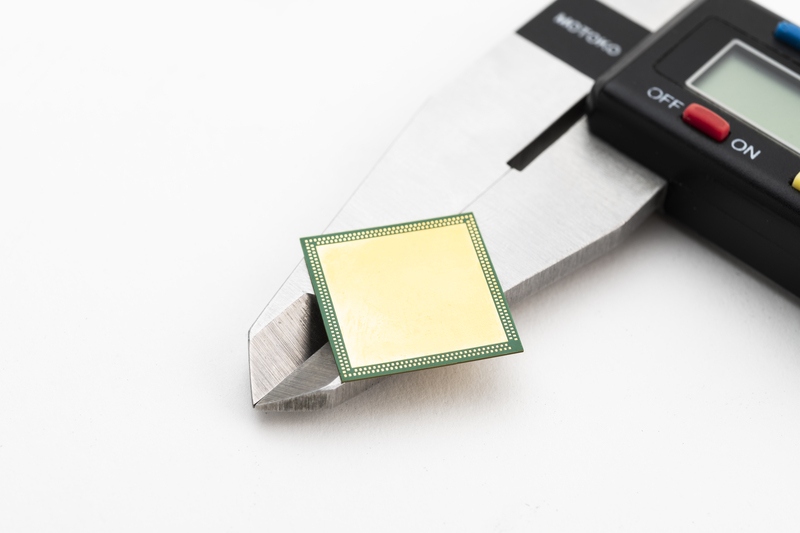

Packaging technologies must now evolve to meet market demands for increased complexity and performance levels required from high-end systems and components. This includes miniaturization, high-speed data transfer, enhanced reliability and more, where issues such as density, thermal management, CTE mismatch and interconnections are of paramount importance.

Successful design concepts largely depend on selecting the optimum System-in-Package (SiP) configuration, based on specific requirements for each application. They must also take into consideration the availability of each and every component to be integrated into a SiP design; using the optimum technologies; interconnect techniques, die attach, and seal or encapsulation methods.

iNPACK capabilities include

NPI

Process Design

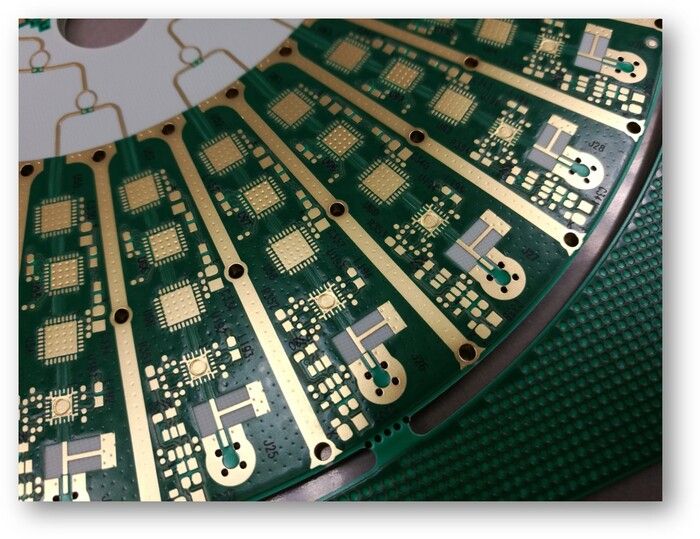

PCB, Substrate

IC Packaging

System Level

iNPACK Relevant content

See All Articles

articles

PCB Design for Radio Frequency & Microwave Module solutions

Learn about our advanced PCB design solutions offering high-performance Thermal Management options for Radio Frequency & Microwave applications.

articles

When is a Miniaturized PCBA the Right Option for You?

articles