Thermal Management

Power dissipation and thermal management are major considerations in advanced chip design, posing several challenges that critically impact performance and functionality. Key issues include: Increased heat generation, performance degradation, limited thermal budget, reduced efficiency, plus packaging and design complexities. iNPACK are leaders in the continuous development of new techniques and innovative approaches that provide proven power dissipation solutions in advanced package design.

Critical design aspects to be considered

Major heat-dissipating components

Board size and thickness

Materials, layout, & component placement

Mounting peripherals

Application conditions & environment

Amount of heat to be dissipated

Cooling methods, (fans, heat sinks, etc.)

Our solutions

Cu coins (I-coin, T-coin, custom-coin)

Heat sinks (soldered, conductive adhesive, non conductive)

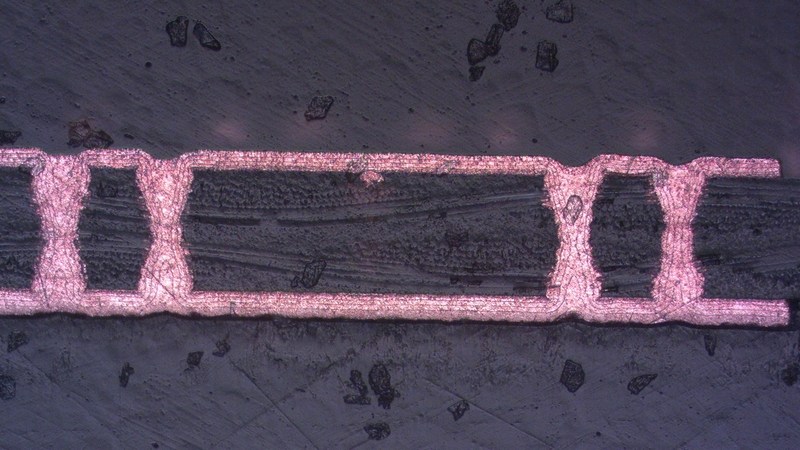

Thermal vias (Cu-filled, epoxy filled)

Cu thickness

Integrated active cooling designs

Specialized assembly solutions

iNPACK Relevant content

See All Articles

articles

X-VIA Technology: Critical for HDI Packages

articles

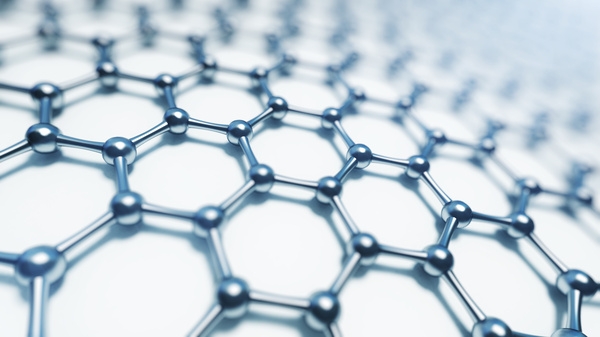

Why Introduce Graphene into Advanced PCBs?

articles

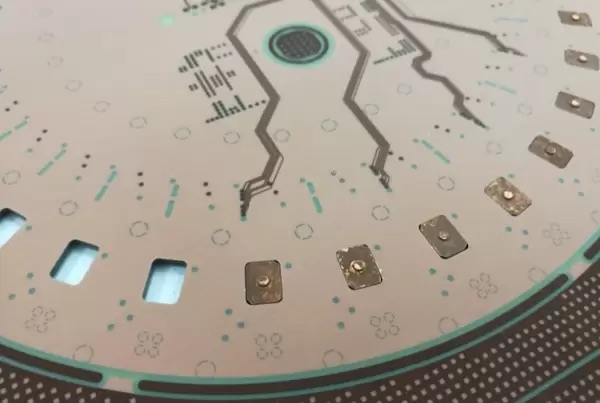

PCB Thermal Management Solutions

PCBs are the first heat management platform that electrical components meet. How you choose to handle the heat very much depends on the power dissipated from constituent components, line losses, board design, circuit editing, and mechanical structure. There are also thermal effects that arise from interconnect options on the board level, vias, transmission lines and assembly pad design.